Yc-8104a Kev Kub Siab Insulating thiab Anti-Corrosion Nano-composite Ceramic Txheej (Grey)

Cov khoom xyaw thiab tsos

(Ib txheej txheej ceramic

YC-8104 xim:pob tshab, liab, daj, xiav, dawb, thiab lwm yam. Kev hloov xim tuaj yeem ua raws li cov neeg siv khoom xav tau

Cov khoom siv tau

Cov nplaim ntawm ntau yam khoom siv xws li cov lauj kaub uas tsis lo rau hauv cov lauj kaub tuaj yeem ua los ntawm hlau, hlau mos, hlau carbon, hlau tsis xeb, hlau txhuas, hlau titanium, hlau alloy kub siab, iav microcrystalline, ceramics, thiab lwm yam alloys.

Kub siv tau

- Qhov kub siab tshaj plaws tiv taus yog 800 ℃, thiab qhov kub ua haujlwm ntev yog nyob rau hauv 600 ℃. Nws tiv taus kev yaig ncaj qha los ntawm cov nplaim taws lossis cov pa roj kub siab.

- Qhov kub thiab txias ntawm cov txheej yuav txawv raws li qhov kub thiab txias ntawm cov substrates sib txawv. Tiv taus txias thiab cua sov thiab thermal co.

Cov yam ntxwv ntawm cov khoom

1. Nano-coatings yog cawv-raws li, muaj kev nyab xeeb, ib puag ncig zoo thiab tsis muaj tshuaj lom.

2. Nano-composite ceramics ua tiav qhov ntom thiab du vitrification ntawm qhov kub qis ntawm 180 ℃, uas yog lub zog txuag thiab zoo nkauj.

3. Kev tiv thaiv tshuaj lom neeg: Kev tiv thaiv kub, kev tiv thaiv kua qaub, kev tiv thaiv alkali, kev rwb thaiv tsev, kev tiv thaiv kub siab, thiab kev tiv thaiv cov khoom siv tshuaj lom neeg, thiab lwm yam.

4. Lub txheej txheej tuaj yeem ua tiav qhov tuab ntawm 50 microns ntawm qhov kub siab, tiv taus qhov kub siab, txias thiab cua sov poob siab, thiab muaj kev tiv thaiv thermal poob siab zoo (tiv taus qhov txias thiab cua sov pauv, thiab yuav tsis tawg lossis tev tawm thaum lub sijhawm ua haujlwm ntawm lub txheej txheej).

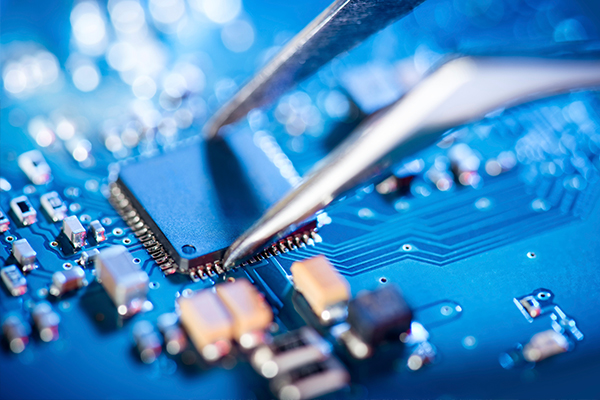

5. Lub txheej nano-inorganic yog ntom thiab muaj kev ua haujlwm rwb thaiv tsev ruaj khov. Nrog lub thickness ntawm 50 microns, nws tuaj yeem tiv taus lub zog rwb thaiv tsev ntawm kwv yees li 3,000 volts.

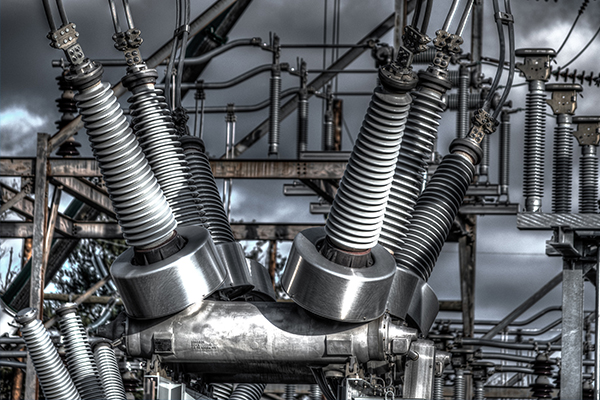

Cov teb thov

1. Cov khoom siv boiler, cov kav dej, cov li qub, cov khoom hloov pauv cua sov, cov radiators;

2. Cov iav microcrystalline, cov cuab yeej thiab cov khoom siv, cov khoom siv kho mob, cov khoom siv tshuaj, thiab cov khoom siv noob caj noob ces;

3. Cov khoom siv kub thiab cov khoom siv ntsuas kub;

4. Cov nto ntawm cov khoom siv hlau, pwm, thiab cov khoom siv casting;

5. Cov khoom siv cua sov hluav taws xob, cov thoob dej, thiab cov thawv;

6. Cov khoom siv hauv tsev me me, cov khoom siv hauv chav ua noj, thiab lwm yam.

7. Cov khoom kub kub rau kev lag luam tshuaj lom neeg thiab hlau.

Txoj kev siv

1. Ib qho khoom sib xyaw: Kaw thiab kho rau 2 txog 3 teev. Cov txheej kho tau lim los ntawm 300-mesh lim. Cov txheej lim tau dhau los ua cov txheej txheem nano-composite ceramic tiav lawm thiab tau tso tseg rau kev siv tom qab. Cov xim seem yuav tsum siv tag hauv 24 teev; txwv tsis pub, nws cov kev ua tau zoo yuav poob qis lossis khov kho.

2. Kev ntxuav cov khoom siv hauv paus: Tshem tawm cov roj thiab xeb, ua kom cov nplaim ntxhib thiab xuab zeb, xuab zeb nrog Sa2.5 qib lossis siab dua, qhov zoo tshaj plaws yog ua tiav los ntawm xuab zeb nrog 46-mesh corundum (dawb corundum).

3. Qhov kub thiab txias: 180 ℃ rau 30 feeb

4. Txoj kev tsim kho

Txau: Nws raug pom zoo kom cov tuab txau yuav tsum tsis pub dhau 50 microns.

5. Kev kho cov cuab yeej txheej thiab kev kho txheej

Kev siv cov cuab yeej txheej: Ntxuav kom huv si nrog anhydrous ethanol, ziab nrog cua compressed thiab khaws cia.

6. Kev kho txheej: Tom qab txau tshuaj, cia nws qhuav ntawm qhov chaw li 30 feeb. Tom qab ntawd, muab tso rau hauv qhov cub uas tau teeb tsa ntawm 180 degrees thiab ua kom sov li 30 feeb. Tom qab txias, coj nws tawm.

Unique rau Youcai

1. Kev ruaj khov ntawm kev siv tshuab

Tom qab kev sim ua tib zoo, cov txheej txheem thev naus laus zis aerospace-grade nanocomposite ceramic tseem ruaj khov nyob rau hauv cov xwm txheej hnyav, tiv taus qhov kub siab, thermal shock thiab tshuaj lom neeg corrosion.

2. Kev siv tshuab nano-dispersion

Cov txheej txheem dispersion tshwj xeeb ua kom ntseeg tau tias cov nanoparticles tau faib sib npaug hauv cov txheej, zam kev sib sau ua ke. Kev kho interface zoo txhim kho kev sib txuas ntawm cov khoom me me, txhim kho lub zog sib txuas ntawm cov txheej thiab cov substrate nrog rau kev ua tau zoo tag nrho.

3. Kev tswj hwm txheej txheem

Cov qauv tsim thiab cov txheej txheem sib xyaw ua rau kev ua haujlwm ntawm cov txheej txheem tuaj yeem hloov kho tau, xws li qhov nyuaj, kev tiv thaiv kev hnav thiab kev ruaj khov thermal, ua tau raws li qhov xav tau ntawm ntau yam kev siv.

4. Cov yam ntxwv ntawm cov qauv micro-nano:

Cov khoom me me Nanocomposite ceramic qhwv cov khoom me me hauv micrometer, sau cov qhov sib txawv, tsim cov txheej tuab, thiab txhim kho qhov compactness thiab corrosion tsis kam. Lub caij no, cov nanoparticles nkag mus rau hauv qhov chaw ntawm lub substrate, tsim cov hlau-ceramic interphase, uas txhim kho lub zog sib txuas thiab lub zog tag nrho.

Txoj cai tshawb fawb thiab kev txhim kho

1. Qhov teeb meem sib phim ntawm kev nthuav dav thermal:Cov coefficients ntawm thermal expansion ntawm cov hlau thiab cov khoom siv ceramic feem ntau txawv thaum lub sijhawm cua sov thiab txias. Qhov no yuav ua rau muaj cov microcracks hauv cov txheej thaum lub sijhawm kub cycling, lossis txawm tias tev tawm. Txhawm rau daws qhov teeb meem no, Youcai tau tsim cov ntaub ntawv txheej tshiab uas nws cov coefficient ntawm thermal expansion ze rau ntawm cov hlau substrate, yog li txo cov kev ntxhov siab thermal.

2. Kev tiv thaiv kev kub hnyiab thiab kev co thermal:Thaum cov hlau txheej hloov pauv sai sai ntawm qhov kub thiab txias siab thiab qis, nws yuav tsum muaj peev xwm tiv taus qhov kev ntxhov siab thermal tsis muaj kev puas tsuaj. Qhov no yuav tsum tau kom cov txheej muaj kev tiv thaiv thermal zoo heev. Los ntawm kev ua kom zoo dua cov qauv ntawm cov txheej, xws li kev nce tus lej ntawm cov theem sib txuas thiab txo qhov loj ntawm cov noob, Youcai tuaj yeem txhim kho nws qhov kev tiv thaiv thermal poob siab.

3. Lub zog sib txuas:Lub zog sib txuas ntawm cov txheej thiab cov hlau substrate yog qhov tseem ceeb rau kev ruaj khov thiab kev ua haujlwm ntev ntawm cov txheej. Txhawm rau txhim kho lub zog sib txuas, Youcai qhia txog txheej nruab nrab lossis txheej hloov pauv ntawm cov txheej thiab cov substrate kom txhim kho qhov ntub thiab kev sib txuas tshuaj lom neeg ntawm ob qho.